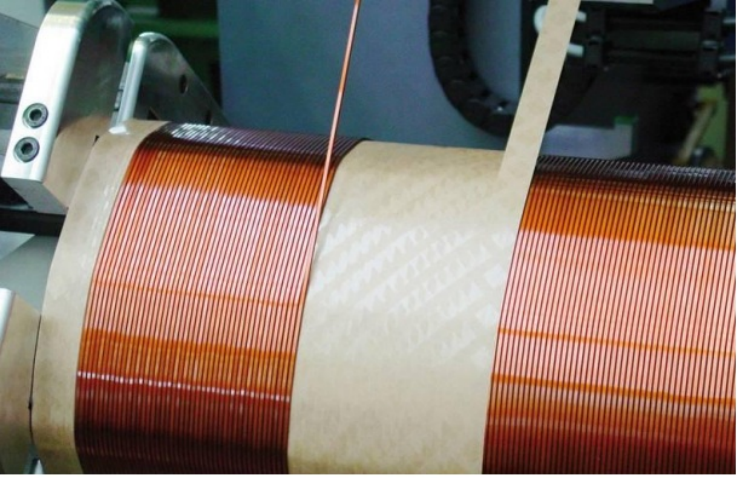

Chinese Wire winding machine (with strip gradual insulation) for high voltage coils of distribution transformers

The machine can perform windings using the strip graded insulation giving extreme flexibility of use which, together with the software, enables different distribution modes for the insulating material.

Automatic Wire Winding Machine

1.General:

H.V.Coil Winding Machine for Distribution Transformers, China

Chinese Wire winding machine (with strip gradual insulation) for high voltage coils of distribution transformers

The machine can perform windings using the strip graded insulation giving extreme flexibility of use which, together with the software, enables different distribution modes for the insulating material.

Gradual Strip insulation

Automatic calculation of stops for taps, cooling ducts etc. ;

Flexible software

It consists of :

Winding Machine;

Auto-wire-laying-device;

Layer-insulation-feeder;

Round/flat-wire-tension-adjusting-device;

Pneumatic system;

PLC control and Servo motor system;

HMI touch screen.

2.Main technical data

| No. | Parameters | AWW-800 | AWW-1100 |

| 1 | Center height | 850-950mm | 850-950mm |

| 2 | Winding shaft center distance | 200-1000 mm | 200-1300 mm |

| 3 | Working torque | ≤500 N·M | ≤1000 N·M |

| 4 | Rotation speed | 0-240r/min | |

| 5 | Motor power | 5.5KW | |

| 6 | Speed adjust | Stepless, frequency conversion speed adjustment | |

| 7 | Workpiece diameter | OD≤800mm; ID≥80mm | |

| 8 | Max. workpiece weight | 1000kg | |

| 9 | Max. number of laps counting | 9999.9 | |

| 10 | Enamalled wire specification and number | Φ0.3mm—Φ5mm; 1 piece | |

| 11 | Flat wire and number | Max. 20×5mm; 2 pieces | |

| 12 | Number of layer insulation shaft | 1,3 | |

| 13 | Number of wire-payoff-rack | Flat wire rack:2pcs | |

| Emamalled wire rack: 1pc | |||

| 14 | Min. gap between wires | 0.01mm | |

| 15 | Mode of counting | 5-digital display, total no. of laps can be preset.Within the total no. of laps, it can be divided into several sections of sub-preset.Can be reverse counting. Can keep record in case of power failure. | |

| 16 | Power supply | 380V/50Hz; 5.5KW | |

![]()

3. Function and Features

3.1. Using mechanical gear speed adjusting system, with high efficiency and low noise.

3.2. There is pneumatic brake for main winding shaft, sensitive and reliable

3.3. With Inverter to adjust winding speed to best status.

3.4. Speed adjust range is wide, accurate and stable.

3.5. With auto wire-laying function.

3.6. With servo-motor, HMI and PLC control system.

Use ball-screw-drive and linear-guide-rail to ensure accurate wire laying.

3.7. Auto-wire-laying and winding are synchronous.

3.8. Tension is adjustble, with tension buffering function.

3.9. Before winding, adjust auto-wire-laying, ensure winding is compact.

3.10. With control box on winding machine, easy for operation.

3.11. With rectangular shaft(50×50×Lmm).

3.12. Connection between Faceplate and Rectangular-shaft can be specially made.

Transformer HV coil winding machine, made in China;

HV coil winding machine, made in China;

High voltage coil winding machine, China

transformer high voltage coil winding machine, from China;

distribution transformer high voltage coil winding machine, made in China.

HV coil winding machine manufacturer from China;

H.V.Coil Winding Machine for Distribution Transformers, China;

China H.V.Coil Winding Machine for Distribution Transformers;

Chinese H.V.Coil Winding Machine for Distribution Transformers

Chinese Wire winding machine (with strip gradual insulation) for high voltage coils of distribution transformers;

China Wire winding machine (with strip gradual insulation) for high voltage coils of distribution transformers

Chinese Wire winding machine for high voltage coils of distribution transformers

China Wire winding machine for high voltage coils of distribution transformers

Chinese Wire winding machine (with strip gradual insulation) for high voltage coils of distribution transformers

Transformer Coil winding machine (With Strip Insulation paper), from China;

Chinese winding machine for transformer high voltage coils with strip insulation.

HV coil winding machine with strip insulation, made in China.

With flattening unit for round wire

With Strip insulation decoiler

With dancer roller to control the motor for constant strip tension

You may contact us at:

Email : zswesthouse@vip.163.com

Company web : http://www.zswesthouse.com

WhatsApp&Mobil : 0086 13923325364

Categories

- Transformer drying machine

- Transformer winding machine

- Vaccum Resin Casting Plant

- Vacuum Pressure Impregnation (VPI) Plant

- transformer core processing machine

- Corrugated wall transformer tank production line

- transformer insulation Processing machine

- (Transformer Coil) Hydraulic Pressing Machine

- transformer components

- oil purifier

- other machines

- High voltage electrical testing equipment

Contact Us

- +86-13421423282

- +8613923325364

- zswesthouse@vip.163.com

- +8613923325364